Panel Potentiometers in Instrumentation

Operating Principles and Ideal Applications

Panel potentiometers are commonly employed in all manners of instrumentation equipment used for indicating, measuring, and recording physical quantities or simply to control a function. Instrumentation can be found in many applications including consumer appliances and equipment used for medical, laboratory, communication, and measurement purposes. Panel potentiometers are used to adjust screen display brightness, volume controls, set voltage levels, set sensitivity levels, etc. Although equipment has evolved from analog to digital over the years, many end users continue to prefer a human-to-machine interface on many specialized measuring instruments and in consumer-grade applications.

How does a panel potentiometer work?

While instrumentation engineering is very domain dependent, a common concern is the selection of appropriate controls for the instrument panel that will be used to adjust and/or calibrate the equipment or appliance in question. For this purpose, panel potentiometers are well suited.

In essence, panel potentiometers are variable resistors. Typically, a variable resistor is constructed with phenolic, ceramic or hot molded plastic elements and a carbon or cermet resistive ink printed on the surface. A wiper rides across the element to create the variable resistive output. Wipers are commonly fabricated from stamped phosphor bronze, nickel-silver or from multiple formed wire strands (multi-finger wiper) welded to a tie bar. In high-end potentiometers, the wire tips are typically made of precious metals.

Panel potentiometers are commonly employed as either a voltage divider or a rheostat. As a voltage divider, the potentiometer is powered between the outer terminals, and the variable voltage is read through the center terminal. When the user turns the shaft, the voltage output changes, directing the system to make a change to the function assigned to the control. As a rheostat, the actual resistance is used as the change in signal to drive the change in the assigned function.

What are the ideal applications of panel potentiometers?

Panel potentiometers are selected for instrument panels in a variety of electronic equipment depending on the end application.

Medical equipment such as an ultrasound scanner may need panel potentiometers for adjustment of display brightness, contrast, opacity or image sharpness. Portable vitals monitor equipment and portable

electrocardiogram equipment may use panel potentiometers to control the display brightness and to set frequency and capture rate.

Communications equipment use panel potentiometers to adjust bandwidth, frequency, squelch and microphone gain.

Electronics testing equipment such as an oscilloscope uses panel potentiometers to adjust input voltage, signal position, time/division rate, and other functions. Power supplies use panel potentiometers to adjust voltage output and current output.

Various types of consumer appliances such as blenders, toaster ovens, hand mixers, toasters, waffle irons, electric griddles, juicers, food processors, food steamers, countertop beverage refrigerators, irons and sewing machines all use panel

potentiometers for various functions and controls.

CTS panel potentiometer solutions

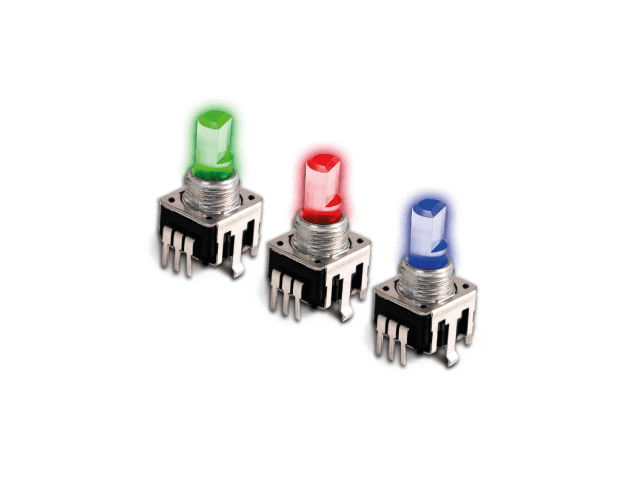

The VR Series family constitute CTS’ panel potentiometer solutions. All models are available with and without bushing and can be configured with horizontal and vertical mount styles. They come with various standard resistance values and a variety of tapers. Shaft length and trim options are available. In addition, the series 12VR offers backlit illuminated shafts. with LEDs available in single, dual and three-color options in a garden variety of colors.

Technical Specifications

| Series |

Element Type |

Terminal Type |

Package Size |

Linear Resistance |

Audio Resistance |

Power |

Rotational Torque |

Rotational Life |

Operating Temperature |

Tandem |

Switch |

| 09VR |

Carbon Composition |

PC Pins |

9mm |

5k-500k Ω |

5k-500k Ω |

0.05W |

10-80

GF∞CM |

5000

Cycles |

-10°C to

+70°C |

- |

- |

| 11VR |

Carbon Composition |

PC Pins |

11mm |

5k-500k Ω |

5k-500k Ω |

0.05W |

30-200

GF∞CM |

15000

Cycles |

-10°C to

+70°C |

Yes |

- |

| 12VR |

Carbon Composition |

PC Pins |

12mm |

5k-250k Ω |

5k-250k Ω |

0.05W |

10-100

GF∞CM |

15000 /

30000

Cycles |

-10°C to

+70°C |

- |

Yes |

| 14VR |

Carbon Composition |

PC Pins |

14mm |

5k-500k Ω |

5k-500k Ω |

0.05W |

30-200

GF∞CM |

15000

Cycles |

-10°C to

+70°C |

Yes |

- |