Product Expansion - Lead-Free Piezoceramics

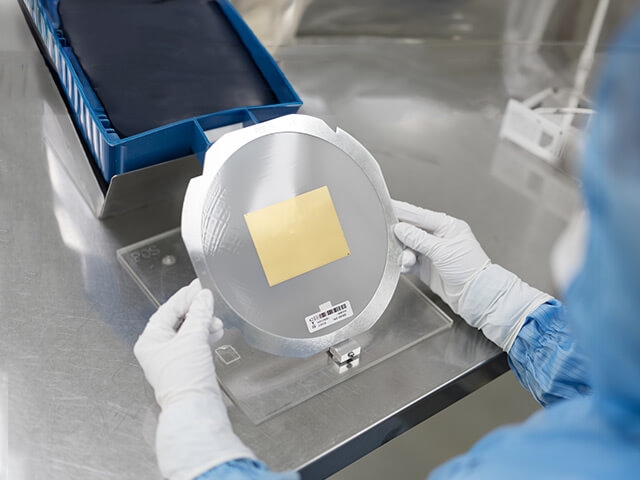

CTS Unveils New Lead-Free Piezoceramic Materials

Answering the industry calls for viable lead-free piezoelectric solutions, CTS is launching a new lead-free program with further optimized materials and four brand new material formulations.

Developing high-performing lead-free piezoceramic materials has been a major point of emphasis for the CTS R&D division for more than two decades. In recent years, our research engineers have made great strides in developing and fine-tuning our lead-free formulations to the point where we now can announce a full lead-free materials program, encapsulated in a brand-new brochure.

The lead-free piezoceramic program encompasses nine distinct materials, based on the KNN, NBT-BT and bismuth titanate systems, respectively - with each material being optimized for specific end-use applications. Four of them - the LF series - are entering the market for the first time with this launch, while the remainder have been further polished and improved upon.

The LF Series and Pz62

The novel LF material series is based on the well-known and thoroughly research lead-free piezoceramic KNN. LF22 and LF41 are modelled after our traditional soft-doped piezoceramic materials, displaying good piezoelectric coupling and relatively high charge coefficients with a low mechanical quality factor. LF22 is well-suited for underwater receivers and hydrophones, hearing aids, flow/level transducers and non-destructive testing. LF41, on the other hand, will excel in medical imaging, shock and acceleration sensors, acoustic emission and actuation applications.

Conversely, LF51 and LF52 are candidates for replacing tradtional hard-doped PZT ceramics. As such, they exhibit high mechanical quality factors and low dielectric losses. Both materials are ideal for high-power ultrasound applications such as medical therapeutics, ultrasonic cleaning/welding and dental scaling.

Also belonging to the KNN familiy is our Pz62 formulation, characterized by having the highest Curie temperature among our soft materials.

Pz12 and Pz12X

Pz12 and Pz12X are of the NBT-BT system - sodium bismuth titanate that has been modified with barium titanate for a reduced coercive field and improved piezoelectric properties. Pz12 is characterized by having a low dielectric constant and low dielectric dissipation. Its clear thickness vibration mode allows for generation of powerful acoustic waves in the thickness direction. Pz12X show similar characteristics, yet the mechanical quality factor and thickness coupling have been increased at the expense of temperature capability. A good material for acoustic power generation or receiver applications such as single transducer sonars.

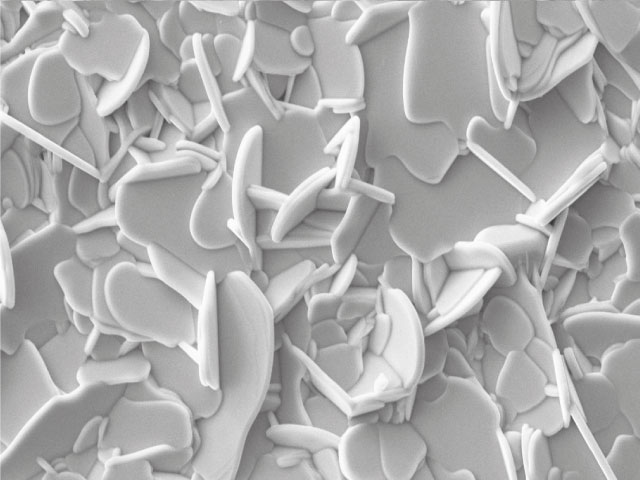

Pz46 and Pz48

Pz46 and Pz48 belongs to a unique group of piezoceramics known as bismuth layer-structured ferroelectrics (BLSF) whose main advantage is their incredibly high Curie temperature, well beyond that of any other piezoceramic material - lead-free or not. Additionally, they offer very stable performances at low temperatures as well. Pz46 and Pz48 are the de facto go-to piezoeramic materials for high-temperature applications, with Curie temperatures of 650°C and 770°C, respectively.

Webinar on lead-free materials and applications

To give you a complete and thorough introduction to our new lead-free program, we have recorded a webinar with three of our ceramics experts, in which they walk you through each material, highlighting their properties and ideal uses. Also, the result of two experimental studies on the applicability of our lead-free materials in various applications are presented. Have a look here:

More information

New lead-free piezoceramic materials brochure

Full piezo line product catalogue

July 10, 2024